By Sun Yi

When a Tibetan carpet unfolds before one’s eyes, it’s hard to tell whether it is a functional household item or a work of art because of its distinct ethnic patterns and colors, soft and delicate texture and exquisite craftsmanship.

As one of the world’s three famous carpets alongside Persian and Turkish carpets, Tibetan carpets are renowned far and wide for their vibrant colors, strong ethnic styles, and distinct regional characteristics.

The Tibetan carpet weaving skills have been passed down for thousands of years. In the Neolithic Age, ancient residents of the Qinghai-Tibet Plateau already formed a unique weaving culture.

According to historical records, 3,500 years ago, nomadic tribes there were adept at weaving woolen fabrics into clothes and quilts to fend off the cold. These weaving techniques were handed down generation after generation, forming the Tibetan carpet weaving skills still in use today.

Carrying profound Tibetan culture, the Tibetan carpet evolved from a simple household item into a work of art. Tibetan carpet weaving also grew into a featured industry, with the products being sold worldwide.

The development of the Tibetan carpet industry has not always been smooth sailing. Traditional Tibetan carpets were mostly handmade in small workshops, with high labor and time costs. Facing competition from lower-cost machine-made carpets produced in bulk, many Tibetan carpet companies saw shrinking orders and losses.

In recent years, affected by factors like the COVID-19 pandemic, hotel occupancy was on a decline, which decreased the demand for carpet replacement, hence a depressed Tibetan carpet market.

The ever-changing market demands have pressed Tibetan carpet companies to take the initiative through innovation. A number of leading Tibetan carpet companies have blazed a trail of innovation for the industry.

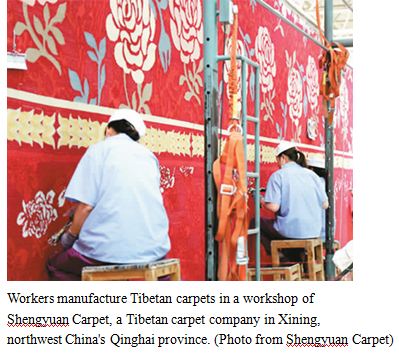

To better incorporate ancient skills into modern life, some Tibetan carpet companies have combined modern carpet weaving techniques with traditional hand-knotting skills.

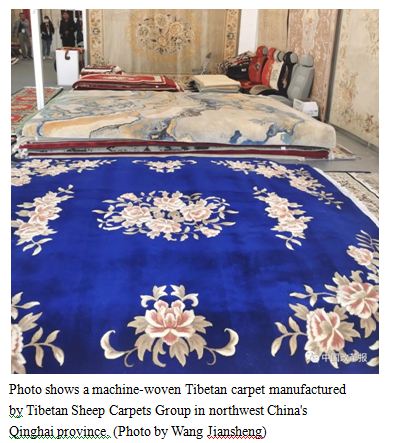

They use special materials and techniques on Tibetan carpets, turning their products from hand-woven carpets to machine-woven, hand-knotted, and fluorescent ones.

They are gradually moving away from mass production and traditional marketing models in the past days, and start embracing digital production methods.

By adopting advanced weaving techniques and innovating pattern designs, a batch of machine-woven Tibetan carpets with cost advantages, fine workmanship, and exquisite patterns are winning the favor of the market.

Nowadays, Tibetan carpet enterprises design patterns and use materials based on customers’ preferences and home decor styles, and customize the sizes of carpets according to the need of customers.

Some Tibetan companies have shifted production from large-scale manufacturing to personalized customization, in order to meet diverse individualized customer demands. They have even developed antibacterial and flame-retardant Tibetan carpets using new technologies to meet modern requirements for eco-friendly home furnishing.

Tibetan carpets from China are seen in many parts of the world, from the Jumeirah Emirates Towers in Dubai to Marriott hotels, and from Las Vegas to Carnival Cruise ships. With continuous innovation in recent years in functions, designs, craftsmanship and standards, Tibetan carpets are increasingly gaining an “international style,” becoming the first choice for many foreign customers.

Tibetan carpets are a treasure of Chinese ethnic traditional crafts. In the interplay between tradition and modernity, in its interaction with the world, the Tibetan carpet industry has undergone an innovative transformation. This not only injects new vitality into the traditional skills passed down over thousands of years, but also provides valuable experience for the industrialization and modernization of other ethnic traditional crafts.