By Li Tielin, People’s Daily

As China’s Shenzhou-16 manned spaceship was recently launched, SBS, Fujian Xunxing Zipper Science & Technology Co., Ltd. (SBS), a zipper manufacturer in Jinjiang, southeast China’s Fujian province has sent its zipper products to the space for a sixth time.

Zippers for spacesuits are by no means the ones used on average clothes. Space missions need super reliable, stable and safe products. Therefore, spacesuit zippers must be able to bear a tensile force of 2,000 newtons, while the average zippers can hold only 760 newtons. Besides, spacesuit zippers should never get stuck.

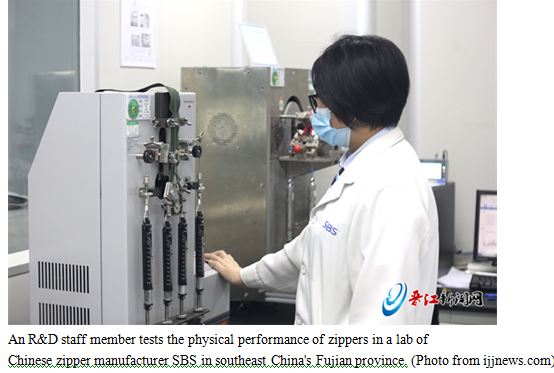

To manufacture reliable zippers for spacesuits, SBS sought support from universities and research institutions for product verification and digital simulation. It developed specialized equipment for the making of spacesuit zippers and optimized relevant parts. Under these efforts, it completed millions of tests and improvements in materials and techniques and finally developed products that meet the standard of space missions.

The progress mirrors the entrepreneurial spirit of SBS, which encourages the company to promote enterprise-university-research institution integration and pursue innovation.

Zippers are small. However, to manufacture them need over 100 procedures and involve more than 10 first-level disciplines and 40 second-level disciplines. Problems occurring in any procedure would impact the quality of products.

It was because of the disciplines and technologies involved, enterprise-university-research institution collaboration became the priority of SBS when it worked for technological breakthroughs.

The hard raw materials of metal zippers would harm manufacturing equipment, so the universities in cooperation with SBS optimized the formulation of metals, which not only lowered production cost, but also lifted the quality of zippers.

Metals are prone to corrosion in certain temperatures and pH range, which shortens the service life of zippers. To cope with this problem, research institutions assisted SBS to conduct tests of surface corrosion and helped it develop anti-corrosion technologies, so as to make its zippers more adaptive.

Enterprises, as experienced market players, know well the demands of their clients. They play an important role in accelerating the commercialization of sci-tech outcomes.

On one hand, enterprises’ own R&D teams can share supply-side information with universities and research institutions, so that the latter are able to find the correct direction of their research. On the other hand, enterprises, by fully exploiting market mechanisms, can significantly lower the risks of universities and research institutions in the application of sci-tech outcomes.

Universities and research institutions are the source of innovative development, while enterprises build platforms for the translation, verification and feedback of technologies. Only when the two sides work together, can the resources for innovation be allocated more efficiently.

Today, tech-ish and innovative products are emerging in the zipper industry. Some zippers are reflective in the dark, and some are equipped with the near-field communication technology, which combine such functions as online interaction, mobile payment and electronic ticket services.

As the textile and garment industry face increasingly diverse and individualized demands, many Chinese zipper manufacturers are building a stronger sci-tech foundation to cope with the fierce market competition.

Practice proves that boosting the principal role of enterprises in innovation, enhancing the enterprise-led collaboration among enterprises, universities and research institutions, and improving technological transformation and commercialization will lead traditional industries toward a wider path of innovation.